Maxcraft assisted this customer with importing this Piper Malibu from the United States, along with minor avionics upgrades. Upon opening up the panel to install some small items, we discovered one of the worst wired aircraft we have ever seen. Problem after problem was discovered as we attempted to resolve all the issues. In the end we believe we found every issue and this Malibu has been flying snag-free since leaving Maxcraft.

Piper Malibu Import and Rectification

1985 Piper PA-46-310P Malibu

Aircraft & Owner:

The Piper Malibu is a single engine, pressurized high-performance aircraft. The PA-46-310P was the first production variant of the Malibu and obtained FAA certification in 1983. This Malibu was purchased primarily to quickly fly between Pitt Meadows and the British Columbia interior where the customer lives and works.

Need:

Our customer was searching for an aircraft to buy with the capabilities of the Malibu. While deciding between mainly a Piper Malibu and an Extra 400, Maxcraft had both aircraft type in our hangar. We invited the customer to see both of these in person. After more consideration, the customer decided to go with the Malibu and found one for sale in the United States. After a thorough prepurchase inspection was completed by a PA-46 expert Maxcraft recommended, the customer decided this was the airplane for him.

Maxcraft was tasked with completing the import process to bring the US registered Malibu into Canada and obtain all the relevant documents to register and make it airworthy in Canada. Along with the import we also planned to complete some very minor avionics upgrades, as it came equipped with a G500 primary flight display, and a GTN 750, there was little need to make any major changes to the avionics.

NEW EQUIPMENT LIST

| GTX 345 | ADS-B In/Out Transponder (Garmin) |

| WX-500 | StormScope + Antenna (BFGoodrich Aerospace) |

| FlightStream 510 | Wireless Cockpit Connectivity (Garmin) |

| TA202 | High Power USB Chargers (Mid-Continent Instruments) x2 |

Maxcraft Solution:

Maxcraft provided a turnkey solution for the importation and registration of this Piper Malibu from the United States to Canada. This included obtaining certificates of registration and airworthiness, verifying all the logbook entries, and replacing the old tail number with the new Canadian one.

After completing the import, we installed two high power USB chargers from Mid-Continent. One in the cockpit for the pilot, and one in the rear cabin for passengers to keep their devices charged. We also installed Garmin’s FlightSteam 510 into the GTN 750 which allows for wireless transferring of flight plans from a compatible app such as Garmin Pilot or ForeFlight, along with wireless database updates which will then sync to the G500 primary flight display behind the scenes.

The Story:

During the prepurchase inspection, everything on the aircraft looked very good. During an oil sample analysis, some metal shavings were found which almost made our customer move on to the next aircraft, but they decided to go ahead with the purchase anticipating overhauling the engine almost immediately after purchase. It turns out much of the metal was due to the aircraft not being flown often by the previous owner and the engine didn’t require overhaul and has flown perfectly to this day. While all the avionics checked out during the prebuy, avionics aren’t typically inspected rigorously, they are simply function checked without removing any access panels or checking wiring.

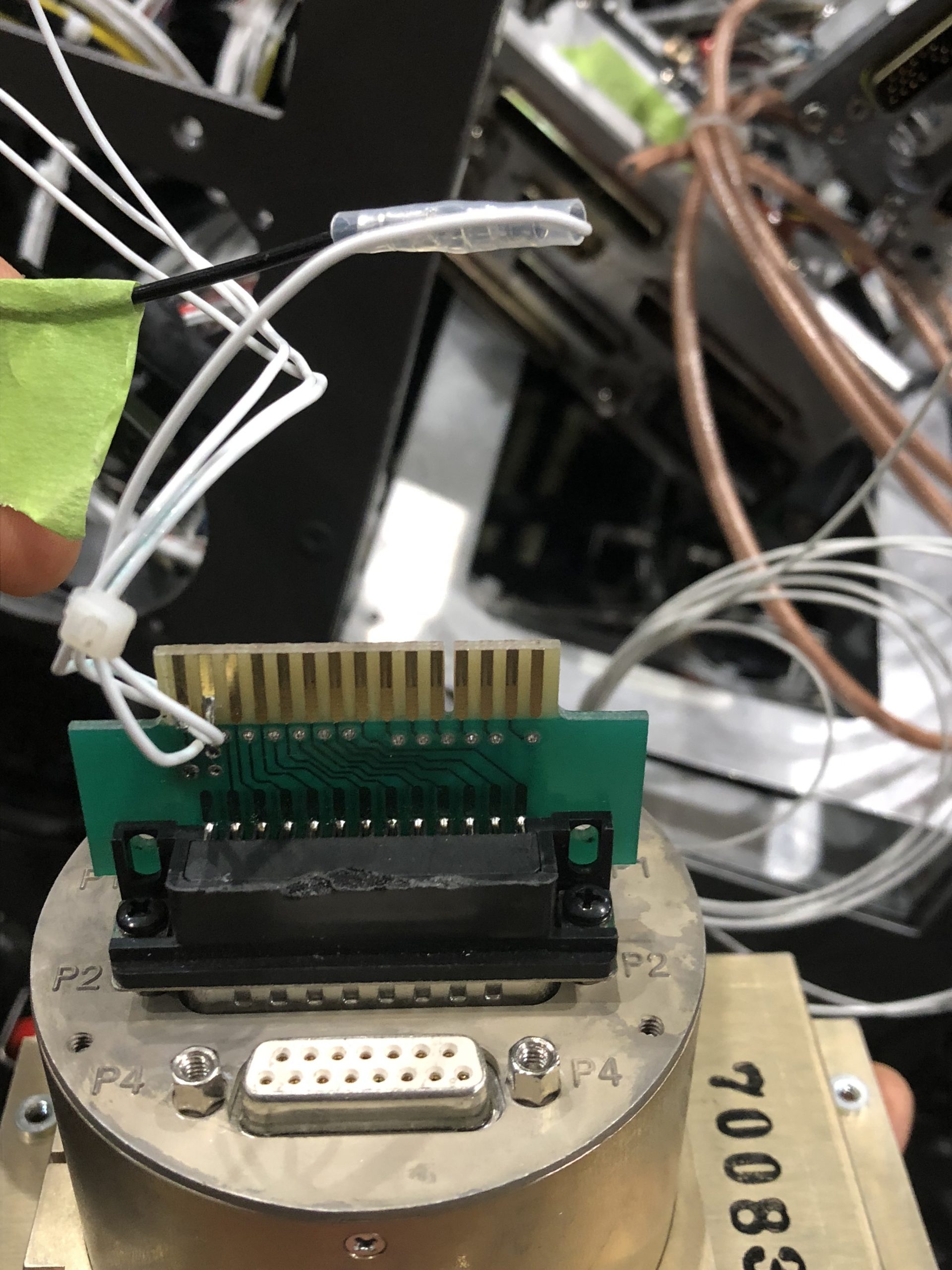

During the ferry flight from the United States to Maxcraft, the transponder was found to not be in compliance with the ADS-B mandate requiring ADS-B “out” to fly in certain airspace in the United States. After arriving at our facility, we found the transponder had not been installed in accordance with the supplemental type certificate, nor was it properly certified in the logbook. Due to the lack of traceability, we decided to simplify things and remove the KT74 transponder and replace it with a GTX 345 from Garmin which would also integrate with the GTN 750.

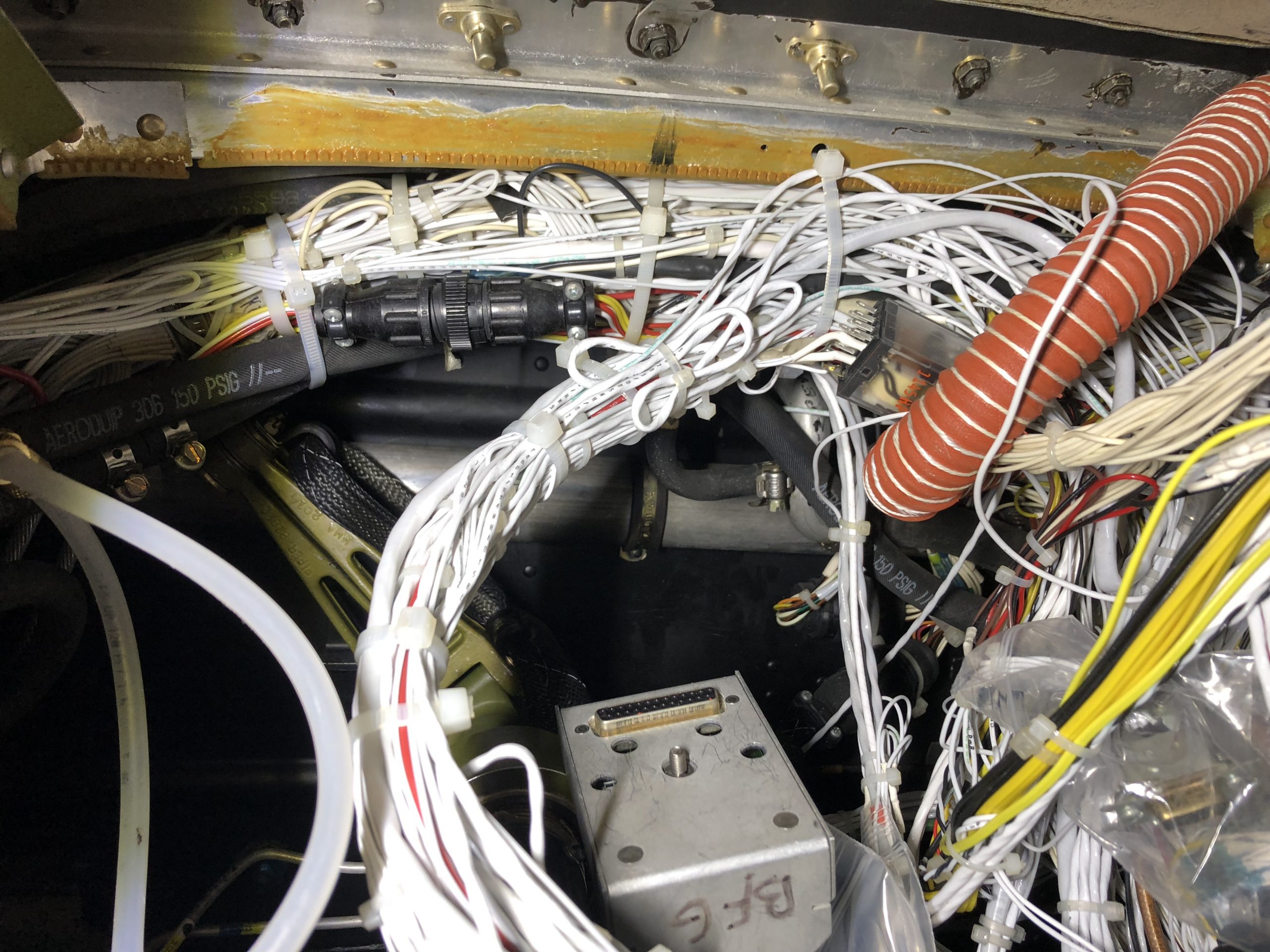

Upon removing the panel, we discovered one of the worst wired aircraft we had ever seen over Maxcraft’s many years. Wiring from systems which had been removed from the aircraft years ago was found throughout the aircraft, with much of it stowed incorrectly. Wiring bundles were very messy with cables run over zip ties on top of more zip ties, which caused chafing issues in some places. Much of the wiring was not done to aeronautical standards. Grounds and power connectors for new equipment was spliced into the connectors from old systems instead of routing new wires to ground and a circuit breaker. Many connections were found using solder splices, many of which were found falling apart and had to be redone using proper methods. We continued to find problem after problem once we began digging deeper.

Multiple items were found inoperative due to not being connected to anything. After troubleshooting the original fuel flow indicator, it was discovered that while installing a digital fuel management system, wiring was disconnected from the required fuel flow indicator and connected to the advisory digital system without routing new wiring to the original fuel flow indicator. The post light for the compass was found not to be wired to anything with no way to obtain power to light up. Multiple annunciators were also not wired to anything making them unserviceable.

Most troubling of all the snags we found were multiple improperly installed antennas. Antennas require approved data when mounted on pressurized structures such as the Malibu. In the United States this is typically Failure to install an antenna properly could cause a leak in the pressure vessel when in flight possibly leading to depressurization. Both the SiriusXM satellite antenna, and the Stormscope antenna were mounted without a doubler or any structural reinforcement whatsoever. At Maxcraft we wouldn’t install an antenna like that on a simpler airframe such as a Cessna 172, let alone a complex pressurized aircraft such as this Malibu. Both antennas were removed so we could perform an inspection to ensure the airframe hadn’t been damaged after many hours of flight with these antennas incorrectly installed. After which we worked with a structures design approval organization (DAO) to obtain an STC to repair and properly mount these antennas.

There were several small lighting issues, the most concerning was the standby attitude indicator not being properly lighted, which is legally required for an instrument flight rules (IFR) certified aircraft. One of the landing gear indicator lights was intermittent due to a shorted wire. The cabin door and baggage compartment lights were not working due to a missing fuse, and the strobe light was unserviceable. All these issues were quickly rectified.

Some of the more minor, but still important things we did while we had the Malibu in our hangar included installing a brand-new battery, replacing the expired fire extinguisher with a brand new one. Installed provisions for a portable oxygen system. Replaced multiple missing or loose static wicks and reinstalled a missing volume knob for the copilot. Maxcraft even went the extra mile and provided the customer with many pilot’s guides for the various avionics found in the Malibu so the owner could familiarize themselves with the avionics equipped in this high-performance aircraft.

While we were working on rectifying the various issues we discovered with the wiring and other systems, we had the 100-hour inspection performed, along with some other powerplant related maintenance done. The propeller, engine, and engine mount were removed from the aircraft to allow for the engine mount to receive a welding repair, and one of the cylinders had to be replaced due to low compressions.

As the Malibu was being registered in Canada, we had to replace the old N tail number with the new Canadian registration. We arranged for a painter to come to our hangar to sand the old registration off, repaint the sides with a matching blue paint, then we applied vinyl decals with the new tail number from Transport Canada.

After finding as many issues as we did with this Malibu, we highly suspected it would be returning often as more problems are discovered over time, however we believe we found every problem as it has been flying snag-free since departing Maxcraft.

The Old Registration Being Removed and Painted Over: