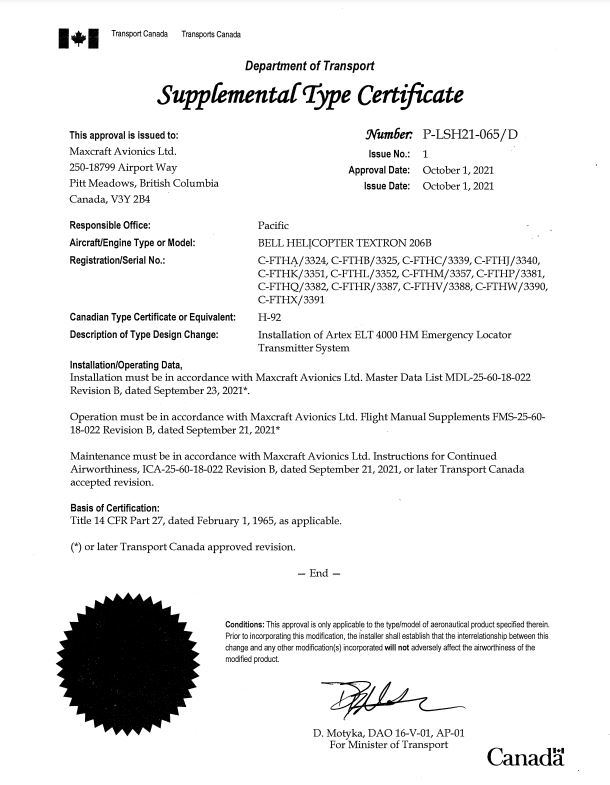

Maxcraft has worked together with Allied Wings on a number of projects to bring keep their fleet of Bell 412CFs and Bell 206Bs into compliance with upcoming regulatory changes. Maxcraft utilized out in house Design Approval Organization (DAO) to create serialized supplemental type certificates (STCs) which meet the requirements of both Transport Canada and the unique requirements of the operator and the Canadian Military. Over the span of several separate projects, we installed ADS-B in and out solutions, as well as Artex’s rotorcraft specific ELT4000HM, which is one of the only 406mhz emergency locator transmitters that doesn’t utilize lithium batteries eliminating the requirement for special approval which is a huge cost to address.

Helicopter Training Fleet Continuous Upgrades

Bell 412 & Bell 206 Fleet

Aircraft & Owner:

Canadian Helicopters is the largest helicopter transportation services company in Canada with 25 bases and a fleet of over 90 light, medium, and heavy lift helicopters. The Bell 412 is a spin off of the Bell 212, with the most noticeable change being the four main rotor blades compared to only two on the 212. The 412CF was a special version built for the Canadian Forces, based on the EP, or Enhanced performance version of the 412. The Bell 206B is a smaller two bladed helicopter. This project involved upgrading a fleet of both 412CFs and 206Bs used for initial rotor wing pilot training in Manitoba. Allied Wings provides contracted flying training and support to the Royal Canadian Air Force.

Need:

This project can be better described as multiple completely separate projects. The first involved making the Bell 412CF fleet ADS-B out compliant by upgrading the existing equipment. Secondly the fleet of Bell 206s the 412CFs required 406mhz emergency locator transmitters. Finally the Bell 206 fleet required an ADS-B out solution as well.

Starting in 2020, the United States Federal Aviation Administration began requiring ADS-B out transponders in order to fly in certain classes of airspace. Although this mandate has not yet made its way up to Canada, many operators are deciding to comply anyway to increase safety, along with opening up the opportunity to operate to and from US airspace.

The key need for this project was compliance with upcoming mandates, and safety. The operator wanted to equip the entire fleet with both 406mhz emergency locator transmitters, and ADS-B transponders. The fleet consisted of 10 Bell 206Bs and 9 412CFs. The new emergency locator transmitters will make it significantly easier to find a downed aircraft in the event of an emergency. When activated, the ELT will transmit a signal with the aircraft’s current location directly to a constellation of satellites where it will then be forwarded to search and rescue personnel who can then take appropriate steps to coordinate a rescue.

NEW EQUIPMENT LIST Bell 412CF

| UNS-1Lw | Flight Management System (Universal Avionics) |

| TDR-94D | ADS-B Diversity Transponder (Collins Aerospace) |

| RTU-4210 | Radio Tuning Unit (Collin Aerospace) |

| 10708 | WAAS GPS Antenna (Universal Avionics) |

| ELT 4000HM | 406mhz Emergency Locator Transmitter (Artex) |

| 110-338 | ELT Rod Antenna (Artex) |

NEW EQUIPMENT LIST Bell 206B

| ELT 4000HM | 406mhz Emergency Locator Transmitter (Artex) |

| 110-338 | ELT Rod Antenna (Artex) |

| GTX 345 | ADS-B Transponder W/WAAS GPS (Garmin) |

| GA 35 | WAAS GPS Antenna (Garmin) |

| AV-74 | Dual Transponder and Distance Measuring Equipment (DME) Antenna (RAMI) |

Maxcraft Solution:

The Bell 412CFs already had the legacy UNS-1L flight management system from Universal Avionics and the Collins TDR-94 Mode C transponders. The TDR-94s were replaced with the Collins TDR-94D diversity ADS-B transponders. To provide accurate and precise location information to the transponders the UNS-1L was replaced with the WAAS capable UNS-1Lw. To meet the operators requirement to have pilot changeable flight IDs, the Collins RTU-4210 will replace the existing RTU-4210F. All of this equipment was installed under a custom serialized supplemental type certificate developed by Maxcraft’s Design Approval Organization (DAO) to meet specific requirements required by both Allied Wings and the Canadian Military. Additionally, custom modification were required to both the ELT controller and the RTU420 to make them night vision goggle compatible, which is a requirement for this fleet.

The ELT 4000HM from Artex was designed specifically for the rotorcraft market and is the only 406mhz ELT that doesn’t use lithium batteries which are subject to “special conditions” for approvals to install, and requires special dangerous goods handling when shipping for service and recertification. The removal of these “special restrictions” eliminates the need for additional certification work to obtain a supplemental type certificate, which is a huge cost to address. This ELT is mounted to the aircraft and transmits it’s signal through an antenna located on the roof. In the event of an emergency, the ELT can be activated either manually by using the remote switch located on the instrument panel, or it will automatically activate if the G-Switch senses an impact. Upon activation it will begin transmitting both a standard ELT tone on 121.5mhz, along with a beacon on 406mhz which will contain current GPS coordinates. This signal will then be relayed to the nearest search and rescue agency, providing first responders an exact location accurate to within 100 meters.

The Bell 206 fleet required changing the existing ELT mounting location due to the size difference between the existing unit and the new Artex 406mhz ELTs. The existing ELTs were removed from the cabin and a new mount was designed and located in the rear baggage compartment. As Maxcraft was the first to install this ELT system in both the 412CF and the 206B we utilized our in-house Design Approval Organization (DAO) to develop and certify a serialized supplemental type certificate (STC) for this installation. These STCs met both Transport Canada’s requirements, and specific operator and Canadian Military requirements.

As the Bell 206s did not have the same advanced flight management system as the 412CFs, a standalone ADS-B transponder with a built-in WAAS GPS source was selected. Originally the customer had planned to use the Garmin GTX 335, which is an ADS-B out transponder, meaning it transmits an ADS-B compliant signal. However, an initiative to add electronic flight bags to the Bell 206s resulted in changing this to the Garmin GTX 345 due to the included Bluetooth data connection to display ADS-B In data. The GTX 345 has become one of our most popular transponder solutions for ADS-B compliance. The GTX 345 is an easy drop-in replacement for existing transponders with a common 1.65” tall form factor. The 1090mhz ADS-B Out transmissions enables an aircraft equipped with the GTX 345 to fly in transponder airspace around the world, including Class A, B, and C in the United States.

The Story:

This project started off with one of the 206Bs being flown from the base in Manitoba to our hangar in Pitt Meadows, British Columbia, which is more than a 951nm trip. We used this first aircraft to develop our supplemental type certificates, as well as perfect our installation. Only after every aspect of the installation was well thought out and operational, and our STC was issued, did we begin work on the remainder of the fleet. This method of completing a single aircraft before starting on the others is extremely economical. This allowed a majority of the fleet to continue operating while we worked out the specifics and obtained approval for the installation. It also gives us an opportunity to find where we can make our process more efficient. It also allowed us to ferry only one of the aircraft to our facility. The remaining aircraft were upgraded at the company’s base in Manitoba where we sent a full team, including avionics, and structures technicians. By prefabricating many wiring bundles, and sheet metal parts before leaving, we were able to reduce time on the road for our crew, and more importantly, downtime for the fleet.