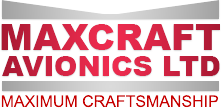

Maxcraft’s first ever installation of the revolutionary Garmin GI-275 electronic flight instrument was in this Cessna 180H on floats. Now it’s ready for anything with an extremely capable IFR configuration paired with the GTN 750, and GFC 500 digital autopilot. With a custom made MaxPanel and lower switch panel, this panel looks better than when it came out of the factory.

Cessna 180H Simple but Highly Capable IFR Install

1969 Cessna 180H on Floats

Aircraft & Owner:

The Cessna 180, also known as the Skywagon, was built between 1953 and 1981. As the predecessor to the popular, and still produced Cessna 182 the C180 was a taildragger intended to be a more capable and powerful option when compared to the C170. The C180H variant could seat up to six people and was powered by a Continental O-470 making 230 horsepower. This C180H was placed on floats. The owner is the founder of a successful video game development company based in Washington State.

Need:

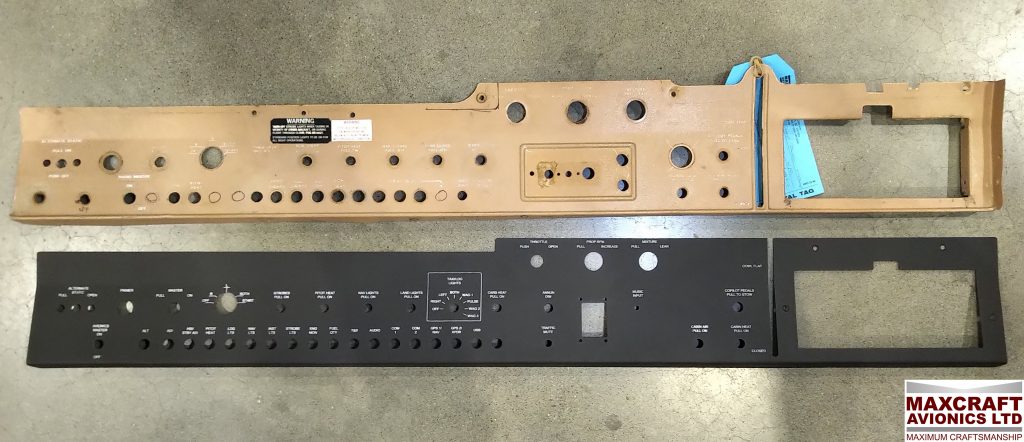

This Cessna 180 came to us with an extremely basic daytime VFR only set of analog instruments. Although it had recently received an upgraded audio panel, VHF comm radio, and an ADS-B out capable transponder, the owner wanted to feel more safe flying in the wide variety of weather we experience on the west coast of North America. A fully IFR capable and reliable panel as well as an autopilot were a must. At the same time, he wanted to replace the factory original plastic panel, which was beginning to show its age, with an all-metal instrument panel, along with a new lower switch panel to match.

NEW EQUIPMENT LIST

| GI275 (x2) | Touchscreen Electronic Flight Instrument (Garmin) x2 |

| GTN 750 | GPS/NAV/COMM/MFD (Garmin) |

| GNX 375 | GPS Navigator and ADS-B Transponder (Garmin) |

| GSB 15 | USB Charing Ports (Garmin) |

| FlightStream 510 | Wireless Cockpit Connectivity (Garmin) |

| GFC 500 | Digital Autopilot (Garmin) |

| Instrument Wedge Lights | LED Supplementary Instrument Lighting (Nulite) |

| MaxPulse | Aircraft Lighting Controller/Pulser (Seaton Engineering Corp) |

| Whelen LED Lights | LED Wing Tip and Anti-Collision Lighting (Whelen Aerospace Technologies) |

| ELT 345 | 121.5/406MHz Emergency Locator Transmitter (ACR) |

| KNE-1255 & JMT-5030 | Panel Mounted iPad Pro Kneeboard (MyGoFlight) |

| MaxPanel | Custom Powder Coated Instrument Panel and Lower Switch Panel (Maxcraft) |

Maxcraft Solution:

While we explored a wide variety of options for this customer, including Garmin’s G3X, and G500 TXi, we ultimately landed on an installation revolving around a pair of Garmin’s G5 electronic flight instrument. However, after the aircraft arrived at our facility and was being prepared to install the G5s Garmin threw a curveball no one was expecting by announcing the GI-275 which was a revolutionary small formfactor touchscreen multifunction display and electronic flight instrument. After some discussions with the customer, we changed our plan and prepared to install two GI-275s instead of the dual G5 setup we originally planned for. This was Maxcraft’s first ever install of the GI-275, and possibly the first in Canada.

An excellent addition for both the G5 for GI275 is the GTN 750 from Garmin. Providing both GPS and radio navigation, as well as a multifunction display. The GNX 375 will provide redundancy for the GPS source and acts as an ADS-B transponder which can be controlled on either the GTN 750, or directly on the GNX 375 screen. The FlightStream 510 installed in the GTN 750 enables a wide variety of wireless connectivity features. The ability to update chart and other databases, transfer flight plans to and from Garmin Pilot or Foreflight, and downloading flight data after touchdown are just some of the additions this tiny card brings to the GTN 750.

We also installed some less noticeable but just as important items such as a new 406MHz emergency locator transmitter (ELT) which transmits a signal to search and rescue satellites when an impact is detected. A panel mount for the customer’s iPad to keep it securely mounted and visible when in flight. A must have for any aircraft today is a plethora of USB charging ports. The Garmin GSB 15 charging port was installed behind the iPad mount keeping wires out of sight and out of the way of flight controls.

Another small but important upgrade we made was replacing most of the lights with LEDs. Both the instrument lighting for night flying, and the exterior position and anti-collision lights were replaced with super bright and long-lasting LED bulbs making instruments easier to read, and the aircraft easier to spot by traffic decreasing the chance of a mid-air collision.

The Story:

As this was our very first time installing the all new GI-275 it presented a unique set of challenges. With any new product we have to learn any quirks that may come with installing it, and learn how to work around these issues. One notable roadblock with this installation was the lack of approval to use the GI-275 with the GFC500 autopilot. The GI-275 was so new, Garmin had not yet received approval to install interface these two products together. Our solution to this was to simply split the install into two phases. The first being the GI-275 and other major avionics. Then the second being the GFC500 autopilot which was planned to be completed shortly after Garmin received their approval.

Once Garmin announced the approval we quickly booked a slot for the customer to return to Maxcraft, then got to work. Along with installing the autopilot we also took the time to upgrade the original GI-275 firmware to the latest version which included some minor fixes which were discovered as the GI-275 became more popular.

Along with replacing the main instrument panel with a metal MaxPanel, we also designed and fabricated a replacement metal lower switch panel to give the entire front end a uniform look. While the classic plastic Cessna switch panel became warped and cracked over the many years of use, the all metal, panel will standup to many decades of use and abuse with our durable powder coating.

While aircraft are undergoing work in our hangar we place down protective covers to prevent any inadvertant damage, including covering the expensive floats on this C180.