Maxcraft teamed up with our partner Heliwelders to transform two tired 1970s Bell 212s into multi-role tactical support helicopters. Completely stripped down and rebuilt from the ground up, with a custom-built workstation to control infrared cameras and spotlights, these helicopters are ready to serve the Bangladesh Airforce.

Military Bell 212 Complete Rewire and Overhaul

Bell 212

Aircraft & Owner:

The Bell 212 was originally introduced in 1968 as a dual engine variant of the UH-1, more commonly known as the Huey. The Bell 212 was developed in 1971 shortly after the military version began production as there was a large demand for a commercial variant of the same helicopter. The Bangladesh Air Force is the branch of the Bangladesh Armed Forces tasked with defending the freedom and sovereignty of Bangladesh in the air, along with providing disaster relief and contributing the UN peacekeeping missions. The Bangladesh Air Force has a wide variety of aircraft in their fleet including many Bell 212s.

Need:

The Bangladesh Air Force had a pair of Bell 212s which were in need of major repairs and overhauls, along with requiring a significant amount of new hardware which included a complete rewire. These helicopters were from the 1970s and were looking very tired, this was a very big project. Heliwelders is a helicopter maintenance, repair, and overhaul (MRO) specializing in major inspections, structural repairs, and paint. Heliwelders is located about 8 miles south-east of Maxcraft at the Langley Airport (CYNJ). Maxcraft teamed up with Heliwelders to propose a solution to the Bangladesh Air Force in a competitive bidding process led by the Bangladesh Ministry of Defence.

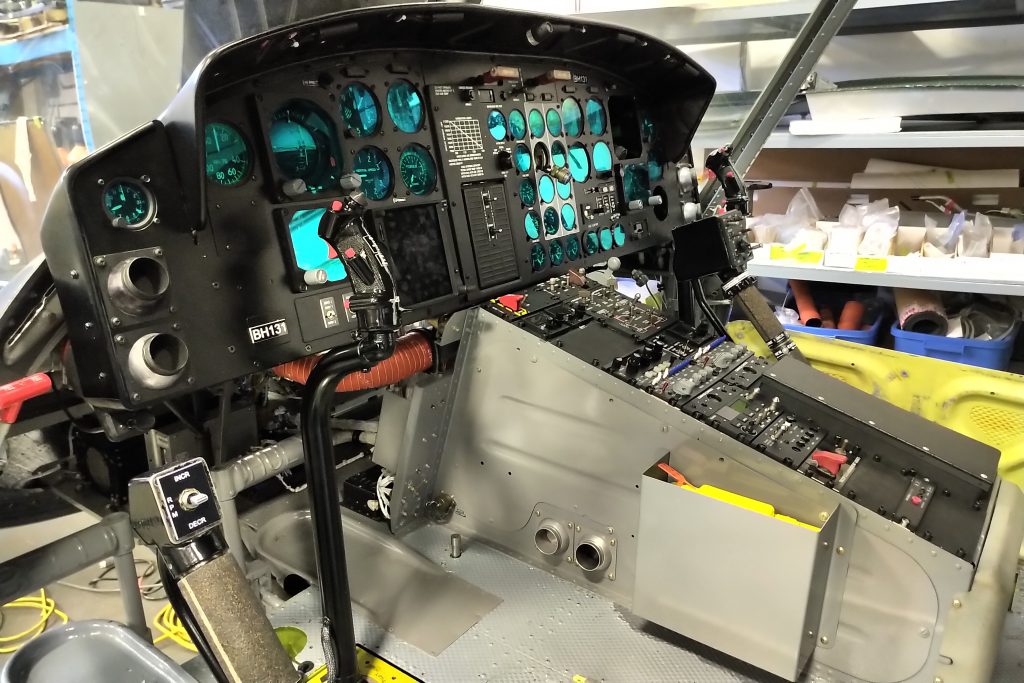

Heliwelders would be performing much of the mechanical and structural work needed to get these helicopters back in the air. Our focus was on the rewire and avionics. This specific pair of helicopters were set to be used for multiple roles, depending on the mission, and would be required to fly in some incredibly harsh conditions. This would require a full IFR package. They also required a state-of-the-art camera system allowing them to search for stranded people at night and in adverse conditions. As these helicopters will be operating in some of Bangladesh’s most remote areas, we wanted to ensure the crew would be safe in the event of a crash. The installation of a 406mhz emergency locator transmitter (ELT) was a must.

One unique aspect of this project was the requirement for all the instruments and switches to be compatible with night vision goggles. All of the instruments and control panels had overlays installed on them preventing the lighting from interfering with the pilot and crew night vision goggles.

NEW EQUIPMENT LIST

| TrakkaCam TC-300 | Night Vision Capable Multi Sensor Surveillance System (Trakka) |

| TM-100 | Map and Video Management System (Trakka) |

| TrakkaBeam A800 | Searchlight System (Trakka) |

| Tactical Officer Workstation | Custom Built Workstation to Operate the Searchlight and Camera |

| NVG Compatibility Upgrade | Instrument and Panel Night Vision Goggle Compatible Lighting Mods/Upgrades |

| RT-600-A | Multi-Band Search and Rescue Radio Direction Finding System (Rhotheta) |

| C406-N | 121.5/406MHz Emergency Locator Transmitter (ACR) |

| LED Lighting | LED Position and Anticollision Lights (Whelen Aerospace Technologies) |

| N301 | Audio Panels (Cobham) |

| CVR-120A | Cockpit Voice Recorder [CVR] (Universal Avionics) |

REWORKED EQUIPMENT LIST

| GTN 750H | GPS/NAV/COMM/MFD (Garmin) |

| GWX 75 | Digital Doppler Enabled Aviation Radar (Garmin) |

| GTX 345R | Remote-mount ADS-B “In”/”Out” Transponder (Garmin) |

| GWX 70H | Weather Radar (Garmin) |

| GTS 825 | Traffic Advisory System (Garmin) |

Maxcraft Solution:

Maxcraft reconfigured and rewired the existing GTN 750 GPS, radio navigator and communicator, and multi-function display. The GTN 750 has an easy to operate touch screen interface and brings the ability to easily plan flights including complex instrument procedures such as IFR departures/arrivals, visual and instrument approaches, and holds. Connecting directly with the weather radar, the GTN 750 can control and display the weather detected by the weather radar.

Trakka Systems designs and manufactures a wide array of gyro-stabilized cameras, searchlights, and other solutions for airborne and marine based intelligence, inspection, and unmanned aerial systems. Two of Trakka’s most popular platforms are the TrakkaCam and the TrakkaBeam. The TrakkaCam is a compact high performance surveillance system with multiple sensors for capturing footage in a wide variety of conditions. These sensors are then run through a sophisticated image processing system allowing the crew to see through fog, haze, low light, and even total darkness. The TrakkaBeam is the most advanced searchlight available, providing 22,500 lumens of directable light. Both the searchlight and the camera system will be controlled from an operator’s workstation we custom fabricated this complex tactical station located in the rear of the helicopter, along with the floor mounting plinth. This workstation will have everything the crew will need to operate the multitude of systems found on-board. It includes an adjustable seat, monitors to display the camera output, a keyboard for data entry, multiple joysticks to maneuver the camera and spotlight, and communications systems to communicate with the pilots, and ground personnel. Fabricating these tactical workstations was the hardest part of the whole project.

The C406-N emergency locator transmitter (ELT) from ACR can transmit the aircrafts latitude and longitude to search and rescue satellites automatically when a crash is detected. This ELT can also transmit the standard emergency tone on 121.5MHz to allow rescue crews to use radio direction finding to home in on the crash site.

The Story:

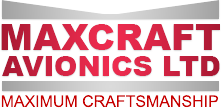

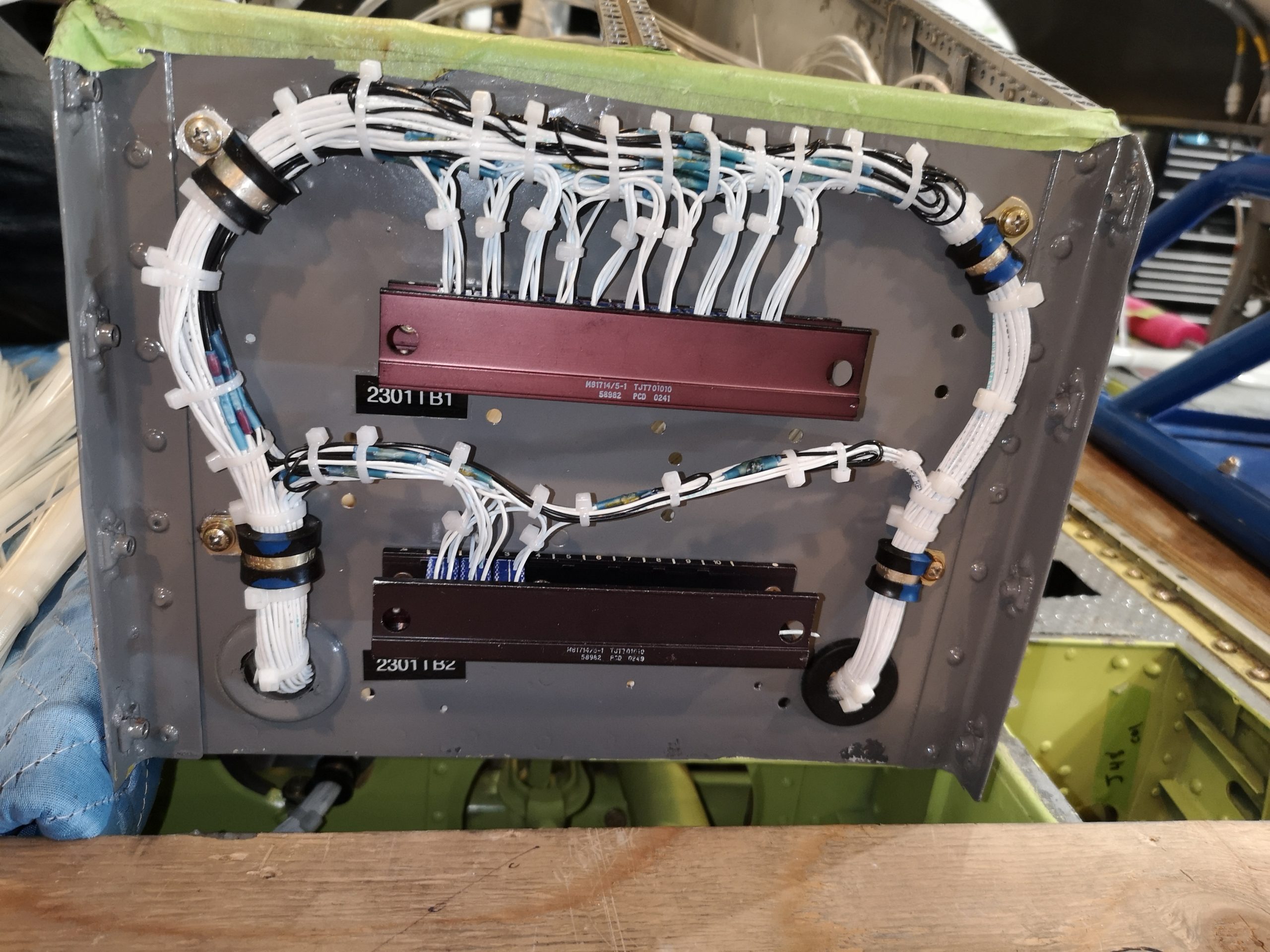

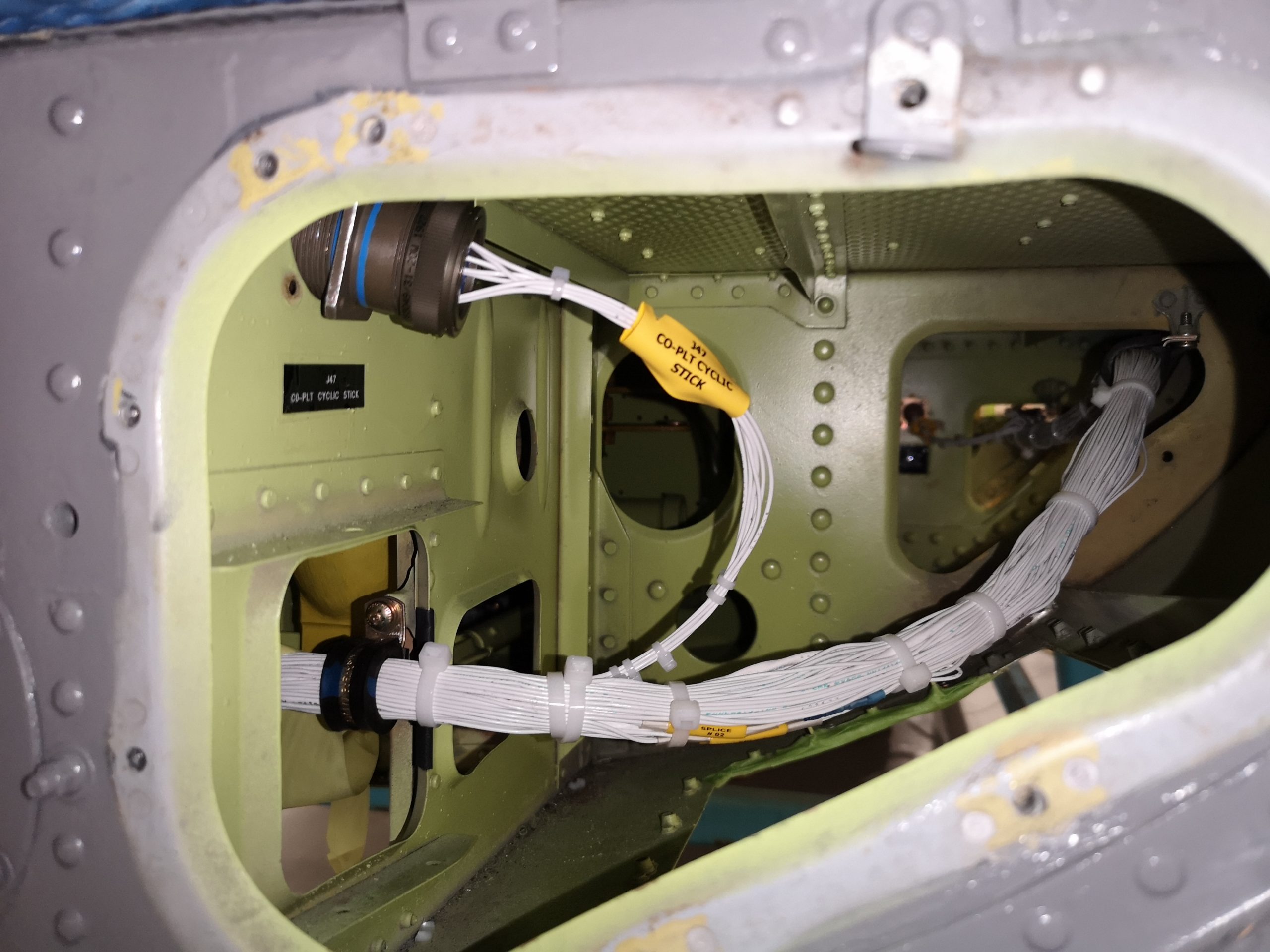

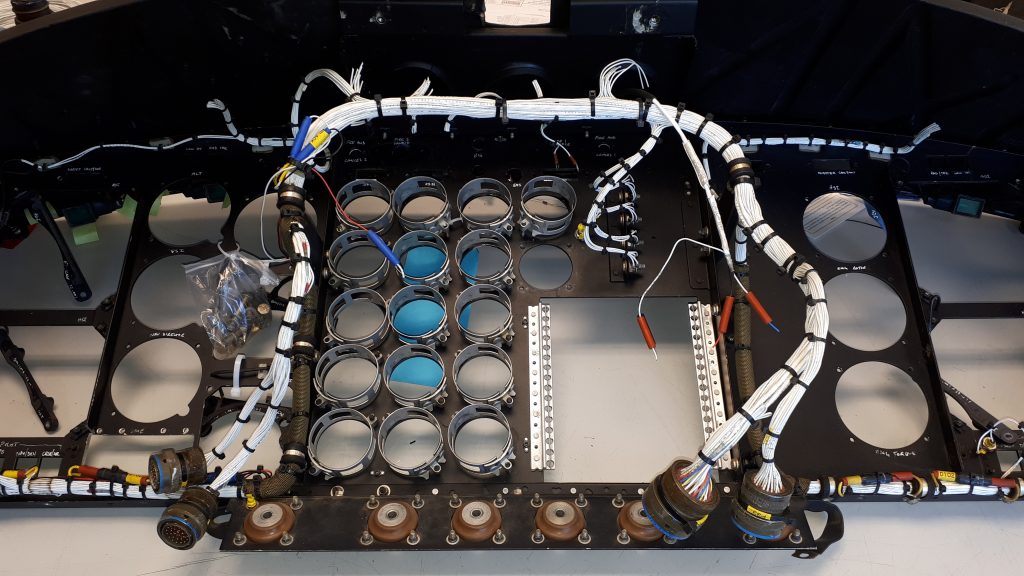

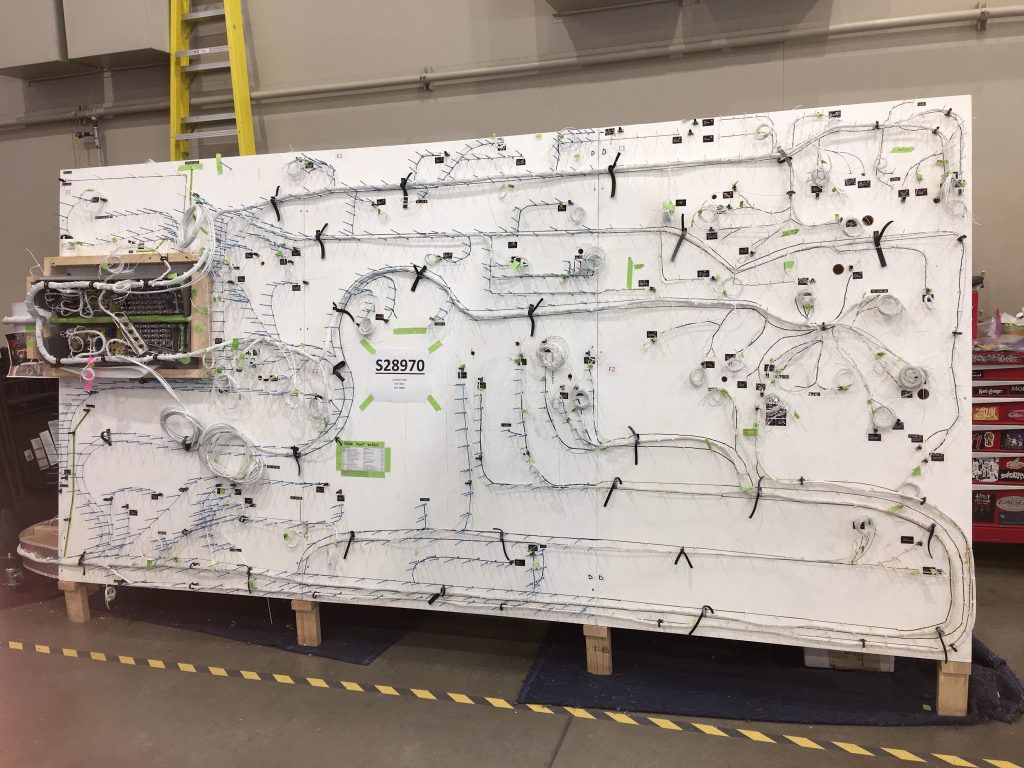

As both of these helicopters were going to undergo complete rewires, we planned for almost all of the wiring to be complete before going into the helicopter. We have massive planning boards which allow us to lay out all the wiring we will be placing in the airframe before. All the connections are terminated, and lengths calculated on this board. After the entire wiring bundle is complete, we take it off the board and lay it in the aircraft and secure it, then connect everything together, making it easier, and more efficient for out technicians to work.

Installed Wire:

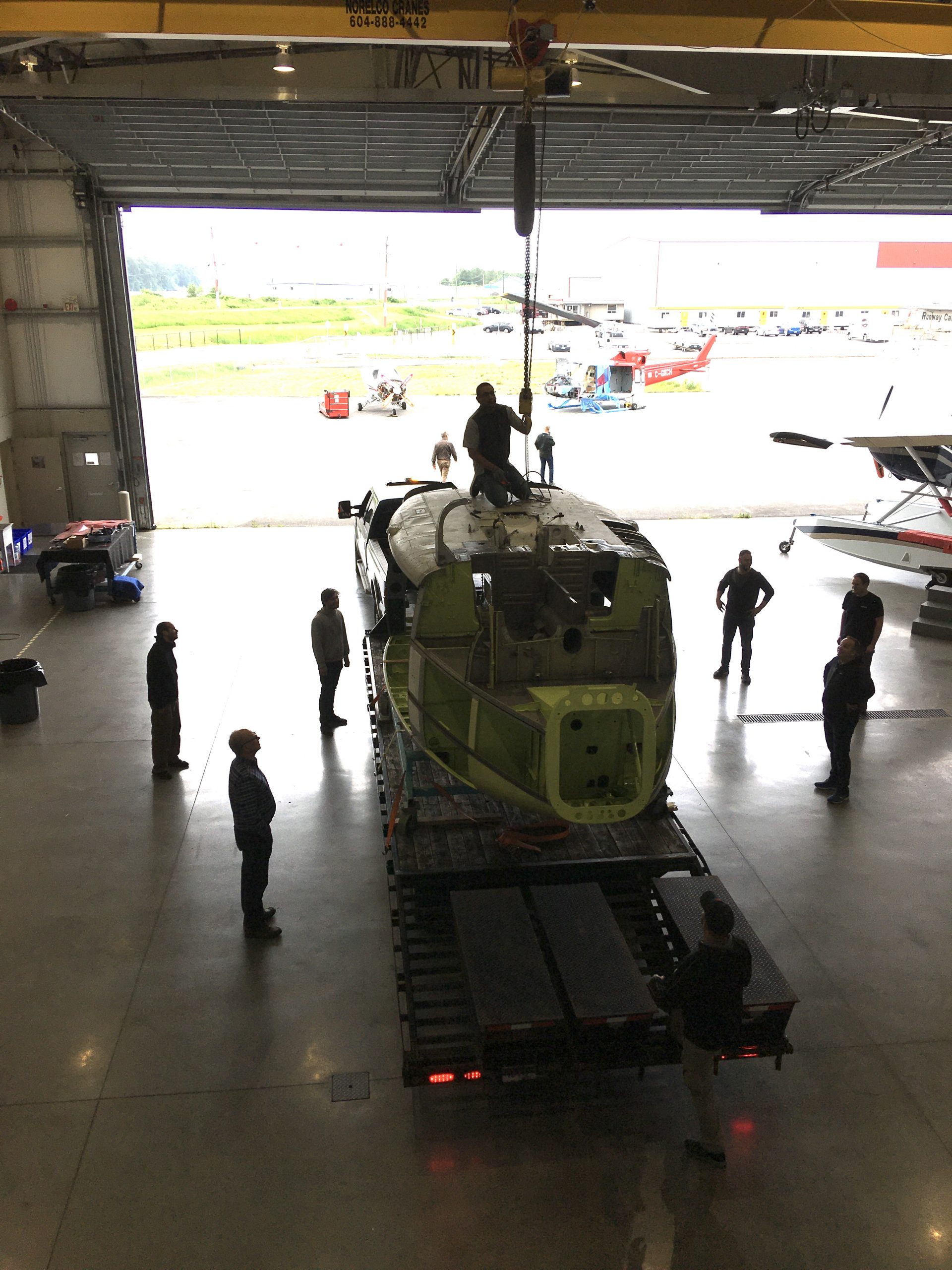

As half of the work would be completed in our hangar, and the other half at Heliwelders, we decided to send the one of the helicopters to each facility. This allowed us to complete all the avionics work in one, while Heliwelders completed the structural and mechanical work on the other. Once we both completed our respective work, the helicopters swapped locations and we got started on installing the avionics in the second, while Heliwelders began structural and mechanical work on the other.

The logistics of a project of this size can become extremely complex. As the aircraft were located in Bangladesh, and were to be operated in Bangladesh in the end, they were loaded into containers and shipped by sea to Vancouver where they were then trucked to our hangar. Once the work was complete, the Bangladesh Air Force sent a flight crew to Canada to complete various in-flight tests. When they were satisfied with our work, we then partially disassembled to aircraft to be placed back into containers to make the return trip back to Bangladesh. When the containers finally returned home to Bangladesh, there was a team of Maxcraft and Heliwelders employees there to reassemble the helicopters and place them into service.

One of the Helicopters Being Moved into our Hangar During the Midway Swap with Heliwelders: