After recently acquiring this Piper Jetprop, the customer ferried the aircraft from Texas, up to our hangar in British Columbia. Our customer wanted this Jetprop to have an avionics suite with a similar look and feel to a jet. Upgrading the G500 display to a G500 TXi, adding a digital engine information system, and Garmin’s G600 autopilot more than met our customer’s expectations.

Piper Jetprop Gets Garmin TXi Upgrade

1986 Piper PA46 Jetprop

Aircraft & Owner:

The Piper PA46 is a single engine, high performance, pressurized airplane. This aircraft is popular with individuals and companies who have a requirement to travel places with speed and reliability. Equipped with flight into known icing (FIKI) capabilities, and the ability to climb into the flight levels, the PA46 is an ideal IFR platform. From the factory, this PA46-310P came equipped with a TSIO-520 piston engine, at some point in it’s life, that engine was removed and a PT6 turbine engine was installed in it’s place using the Rocket Engineering Jetprop STC. The PA46 holds a special place with us here at Maxcraft. Owning one ourselves, and completing many major avionics upgrades on others, we’ve become experts on this airframe and can offer advice on upgrades that may be overlooked by other shops.

The Existing Panel with a Legacy G500 Primary Flight Display

NEW EQUIPMENT LIST

| G500 TXi | Integrated Flight Display with SVT (Garmin) |

| G500 TXi EIS | Dedicated 7” Engine Indication System (Garmin) |

| GI275 | Standby Electronic Flight Instrument (Garmin) |

| GTN 750 Xi | Touchscreen Flight Navigator and Multifunction Display (Garmin) |

| Smart Glide | Dedicated Smart Glide Button (Garmin) |

| GFC 600 | Digital Autopilot with Pitch Trim and Yaw (Garmin) |

| MaxPanel | Custom Powder Coated Instrument Panel (Maxcraft) |

| GSB 15 (x4) | USB Charging Ports (Garmin) |

| GCU 485 | Primary Flight Display Controller (Garmin) |

| ELT 345 | 406mhz Emergency Locator Transmitter (Artex) |

| Insulation | Thermal/Acoustic Insulation |

| Fans | Glare Shield Mounted Avionics Cooling Fans |

Need:

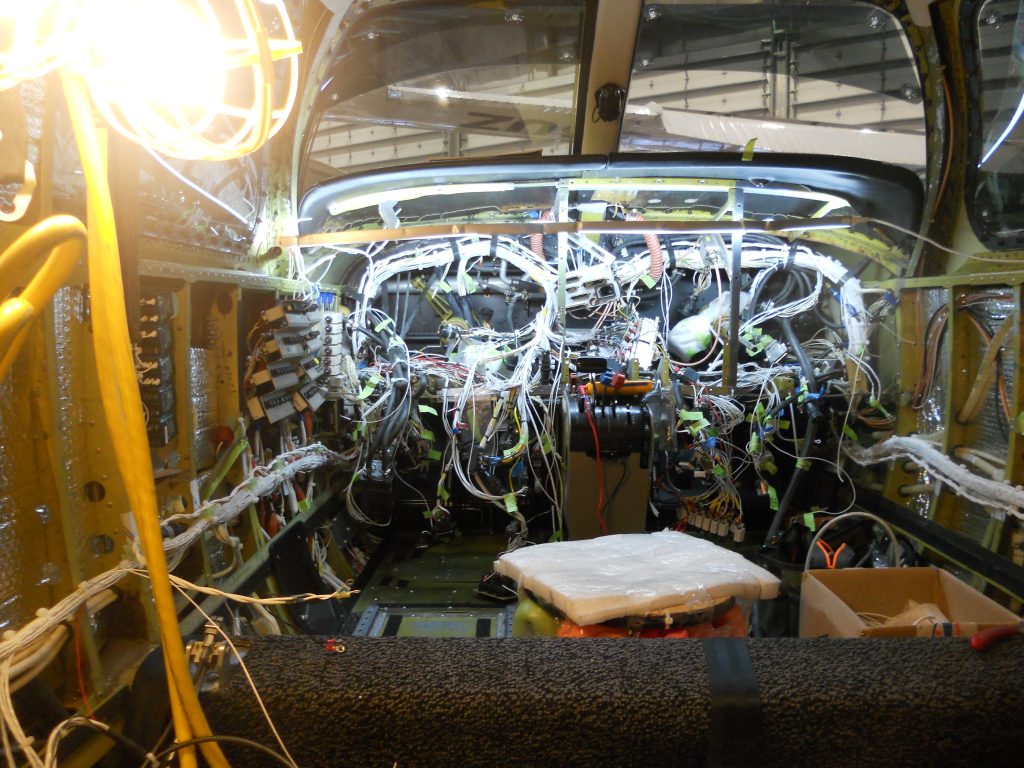

The owner of this aircraft had just recently purchased it and was looking to upgrade to more capable avionics. Our customer wanted to make the avionics in the Jetprop look and feel like the avionics you’d find in a twin-engine jet aircraft. While it came with Garmin’s legacy G500 primary flight display and legacy GTN 750, the owner wanted to upgrade these to the new TXi and Xi variants.

The G500 TXi brings better screen resolution, an easier touchscreen interface, and better processing technology. Upgrading the GTN 750 to the Xi version also gave this aircraft Smart Glide technology adding comfort and reducing pilot workload in the ultra-rare situation the turbine engine fails.

While much of the avionics had been upgraded in the past, the autopilot was still a dated KFC150 which was developed in the 1980s. A new digital autopilot was a must to meet the expectations our customer had.

The original scope of this project also included upgrading the existing Shadin engine trend monitor to a newer model, however once we were well into the project, the customer decided to add Garmin’s G500 TXi engine information system along with a dedicated 7” touchscreen to display all the engine parameters in flight. This allowed us to eliminate both the original engine indication instruments which took up a not insignificant amount of panel space, along with the Shadin Engine Trend Monitor.

The Story:

Garmin’s GFC 600 is one of the most advanced autopilots on the market, bringing new levels of capability and reliability to this Jetprop. The GFC 600 provides superior integration with the G500 TXi, and GTN navigators, and offers pitch, roll, pitch trim, and yaw control through a series of servos connected to the flight controls. The GFC 600 also has a variety of safety enhancing features. Even when the autopilot isn’t engaged, it’s always monitoring the flight parameters to detect a number of unsafe situations such as over/under speed. The GFC 600 will audibly alert the pilot, then begin gently nudging the controls back towards stable flight. Garmin’s dedicated return-to-level (LVL) button will automatically return the aircraft to straight and level flight from any attitude when activated. This can save the day if the aircraft inadvertently enters instrument meteorological conditions.

As this is an aircraft often flown IFR, the GCU 485 primary flight display controller. This unit adds knobs for many commonly used function on the PFD making on the fly adjustments even easier.

To the left of the G500 TXi primary flight display is Garmin’s GI 275 electronic flight instrument. This small 3.25” instrument has a high-resolution touchscreen which displays everything the pilot needs to maintain safe flight, such as altitude, attitude, airspeed, and heading. With a built-in battery backup, the GI 275 will continue providing vital information, even during a complete electrical failure ensuring the aircraft can make it home.

With older 121.5 mhz ELTs becoming less reliable and sparsely monitored, we installed the Artex ELT 345, a 406mhz emergency locator transmitter which transmits a signal to search and rescue satellites in the event of a crash. The ELT is activated either by a built in G-sensor which detects collisions, or by a switch located on the instrument panel. And will provide an exact location to search crews.

One large benefit of our experience with the PA46 lineup is the efficiency which comes with familiarity. Rarely do we take on a PA46 job with many unknown factors. The panel is one area we have perfected with the PA46. While designing our own Malibu’s panel we took the time to perfect the pattern and we now have perfect CAD files that will fit most PA46s. This gives us the opportunity to focus more on the ergonomics of that panel rather than making all the equipment fit. With this customer being experienced in flying jets, he wanted to ensure the panel layout was perfectly ergonomic and supportive of cockpit flows. By the time we were cutting metal we were on our 18th revision of the panel layout, much of this was a result of back and forth with the customer to ensure the layout is exactly what they want to eliminate any regret after flying the aircraft for years.

One large benefit of our experience with the PA46 lineup is the efficiency which comes with familiarity. Rarely do we take on a PA46 job with many unknown factors. The panel is one area we have perfected with the PA46. While designing our own Malibu’s panel we took the time to perfect the pattern and we now have perfect CAD files that will fit most PA46s. This gives us the opportunity to focus more on the ergonomics of that panel rather than making all the equipment fit. With this customer being experienced in flying jets, he wanted to ensure the panel layout was perfectly ergonomic and supportive of cockpit flows. By the time we were cutting metal we were on our 18th revision of the panel layout, much of this was a result of back and forth with the customer to ensure the layout is exactly what they want to eliminate any regret after flying the aircraft for years.

Some minor but still important quality of life improvements we made were adding 4 dual port USB charging stations from Garmin. These will allow both the pilots, and passengers to keep their mobile devices and electronic flight bags charged on even the longest of cross-country flights. With our knowledge of the PA46, we were able to provide this customer with a solution to a problem that plagues many PA46 owners. As a pressurized aircraft, the service ceiling is very high compared to other aircraft. The higher in altitude you go, the colder the outside temperature is. Especially with a turbine engine, which is most happy at high altitudes, the cabin can get extremely cold. We installed a thicker and higher quality insulation under the interior panels to help keep the aircraft warm at altitude, as well as a bit cooler when taxiing on the ground on hot days. With this aircraft being based in Texas, heat is a definite concern, especially for the many expensive avionics located directly in the greenhouse under the windshield. Two large cooling fans were installed on top of the glare shield which serves two purposes. On hot sunny days, the fans will provide additional airflow to the avionics. On cold frosty days, the fans will blow heat from the avionics bay up towards the windshield providing additional defrosting.